According to the latest news from the Langfang Development and Reform Commission: In order to ensure the natural gas supply in Langfang during the winter heating period, the sales price of non-residential pipeline natural gas in Langfang City will be changed from the current 3.16 yuan/m³ from November 1, 2020 to March 31, 2021 The joint increase is 3.55 yuan/m³!

According to observations, non-residential gas prices in many places in Hebei have risen, with an average increase of 44.56%! With the arrival of the heating season, the demand for hot water and heating in the north has increased, and the contradiction between supply and demand of natural gas in winter has become more prominent!

Natural gas heating, under the condition of low gas price and sufficient gas source, has the advantages of low investment, convenient use, unaffected by temperature, and stable effect. However, in the northern region, there is generally insufficient natural gas supply and rising gas prices in winter, resulting in unstable heating effects in winter, high operating costs, and many users are overwhelmed.

PK: Compared with commercial heating of 10,000 square meters, the air source heat pump saves about 41%

The gas price reaches 3.55 yuan/m³. If gas-fired boilers are used for heating, the operating costs of large-scale commercial heating projects will undoubtedly be high, which will definitely be a big burden for Party A.

Compared with gas-fired boiler heating, air source heat pump has many advantages such as environmental protection, energy saving, safety, etc., especially under the policy dividend of reducing general industrial and commercial electricity prices, it can be described as the preferred solution for winter heating of commercial projects.

Below, we take the unit price of energy in Langfang, Hebei as an example, and make a detailed comparison of the two heat sources of air source heat pump and gas boiler——

Assuming a commercial heating project with a heating demand of 10,000 square meters, the indoor heating temperature is 20°C, and the last stage is a strong convection low-temperature radiator or fan disk. The heating time is from November 1 (2020 advance heating) to March 15, 2021 day, a total of 135 days.

According to the "Heating Consumption Index and Heating Design Heat Load Index of Major Cities in the Country", the heat load is 31.23W per square meter, and the design standard is 43.66W.

However, this Weibo editor interviewed dealers with experience in implementing large-scale commercial projects in Langfang, Hebei, and learned that the above-mentioned standards are rarely followed in actual operations. Generally, the heat load configuration is between 45 and 80W, and the calculation is based on 60W here.

During the interview, it was learned that a number of engineering companies in Hebei believed that the calculated temperature outside the heating area in Langfang was -8.3°C. Under such working conditions, the overall energy efficiency ratio of the entire air source heat pump system (including water pumps, etc.) in the winter heating season was 1.8 to 2.5 Between, here we calculate according to 2.2.

The price of natural gas is 3.55/m³, and the price of electricity is calculated at 0.5394 yuan per kilowatt-hour in the flat section.

'

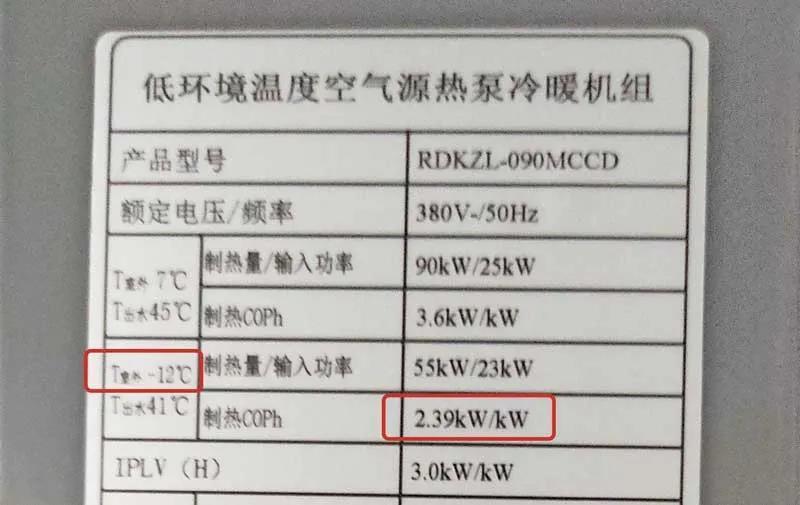

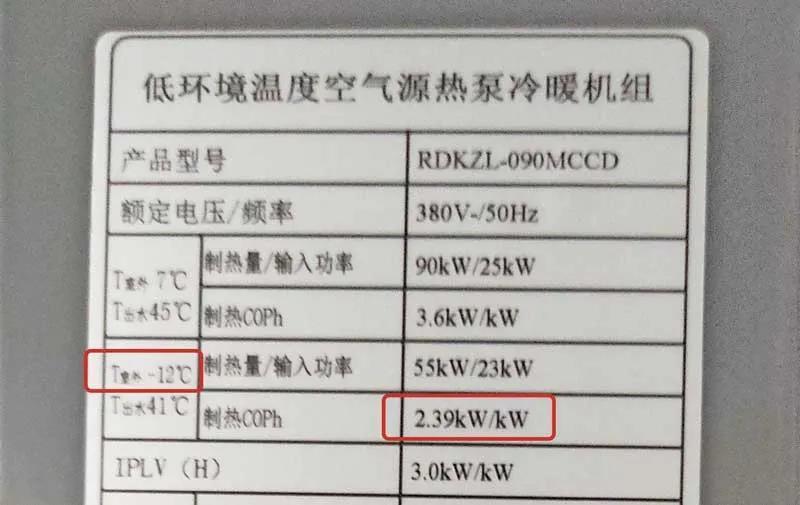

What needs special explanation is: the energy efficiency ratio of the air source heat pump manufacturer’s unit (laboratory test), the energy efficiency ratio is about 2.1~2.8 under the nominal working condition of -12°C (corresponding to 1~3 energy efficiency units), and at -8.3°C Under working conditions, the energy efficiency ratio is generally between 2.5 and 3.2.

Then why is the energy efficiency ratio of the system in actual operation lower than the energy efficiency ratio of the unit?

There are three main influencing factors: one is that there is almost no heat leakage during the laboratory test, but in the actual operation process, the heat leakage is much larger; In the actual operation process, the outlet water temperature is generally higher than this value, such as 50°C or 55°C; third, the laboratory test does not include the energy consumption of the water pump, but in actual operation, in addition to the energy consumption of the main engine, the energy consumption of system components such as water pumps must also be added. Energy consumption!

In addition, the energy efficiency ratio of the system is also related to two points: firstly, the system design level of different levels of engineering companies is very different, and the power consumption varies greatly; secondly, the different heat usage habits of different users also lead to the overall The energy saving of the system varies greatly.

Let's put it this way, for the same house in Hebei, when these factors are added together, the final energy consumption can be doubled, no exaggeration!

Daily operating cost = unit thermal index × heating area × operating time × energy unit price ÷ (energy calorific value × heat transfer efficiency).

Among them, the daily operating cost of the gas boiler: 60×10000×10×3.55÷(1000×10.05×0.85)=2493.4 yuan;

Daily operating cost of air source heat pump: 60×10000×10×0.54÷(1000×1×2.2)=1472.7 yuan.

From the above calculation, it can be concluded that the cost of air source heat pump heating for 135 days is about 198,800 yuan, and the cost of using gas boilers is 336,600 yuan (compared with the gas price of 3.16 yuan/m³, an increase of about 40,000 yuan).

Therefore, compared with gas boiler heating, air source heat pump heating has reduced by 137,800 yuan, saving about 41% of the cost.

Multiple advantages, air source heat pump is more compatible with commercial central heating

Under the country's goal of winning the blue sky defense war, clean heating is the general trend. Regardless of the consideration of energy stability, environmental protection, or the cost of heating operation, air source heat pumps are a more sensible choice for commercial projects to clean and heat in winter than gas boilers.

1. Low cost, high return on investment

Air source heat consumes very little electric energy, absorbs a large amount of low-temperature heat energy in the air, and converts it into high-temperature heat energy through compression by a compressor, with outstanding energy-saving properties. It has been proved by the application in most areas in the north that the comprehensive energy efficiency ratio in the winter heating season is above 2.0.

2. Easy installation, saving time and money

The air source heat pump can be used for heating when it is connected to electricity. Using the power distribution system can effectively avoid the increase of power capacity, and save the investment of digging roads and laying gas pipelines, saving time and money.

3. Electricity supply is stable and electricity price will be lower and lower

The seasonal peak-to-valley difference of natural gas is relatively large (the maximum peak-to-valley difference exceeds 10 times), resulting in a gap in the natural gas heating period and an oversupply in winter.

This is not the case with electricity consumption. With the rapid development of my country's electric power construction, the power supply has formed a situation of oversupply, which can provide a stable power supply, and basically there will be no shortage of power supply.

4. Convenient management, unattended, low maintenance cost

The emission of gas-fired boilers needs to comply with the standard value of the environmental protection department. Therefore, a large amount of annual inspection, testing, and maintenance fees need to be paid every year, ranging from tens of thousands to hundreds of thousands. In addition, it is also necessary to hire a professional boiler worker, and the salary expenditure also needs tens of thousands of yuan a year.

The air source heat pump realizes intelligent control, does not need special guards, saves labor costs, is stable and reliable during equipment operation, and has low maintenance costs.

5. Environmental protection and pollution-free, safe and reliable

The air source heat pump will not produce harmful pollutants; the gas will produce certain emissions during the combustion process, and the environmental protection department also has strict standards for gas boiler gas emissions.

Gas-fired boilers are prone to deflagration during operation, and there is also a risk of leakage, which can easily cause loss of life and property; the air source heat pump realizes the separation of water and electricity, fundamentally eliminating safety hazards such as leakage, explosion and poisoning.

6. Dual-purpose for heating and cooling, saving investment in refrigeration equipment

Gas boilers can only meet the heating needs in winter, and other refrigeration equipment needs to be reinstalled for cooling in summer.

The air source heat pump realizes one machine with two functions, and the end adopts floor heating or fan coil unit. It can be heated in winter and cool in summer at the same time. There is no need to install other refrigeration equipment in summer.

'