Success Stories

A small experience with air source heat pump two-channel system

Published on:

2023-04-20

In the past two years, with the transformation of coal in the north and the upgrading of consumption in the southern market, the combined supply of air source heat pump, floor heating and air conditioning has sprung up. The fundamental reason for the dramatic changes in the market is that consumers' demand for heating and cooling has been upgraded from a functional demand to a comfortable demand. Driven by the overall consumption upgrade, the combined air-source heat pump, floor heating and air-conditioning combined supply technology has been favored by more and more consumers due to its comprehensive advantages in comfort, energy saving and environmental protection. The market for the combined supply system The scale is developing rapidly with a growth rate of more than 200%.

Compared with multi-connected systems and wall-hung boiler heating systems, air source heat pump dual supply systems have higher technical thresholds. In practical applications, there are also various problems that make many dealers daunting. The following small experience is for your reference!

experience 1

Try not to use radiators at the end

For home installation dual supply systems, floor heating and fan coil units are generally used at the end. Some users are limited by various conditions, and there are also radiators or floor fan coils. However, if you can do floor heating, try not to make it into a radiator, otherwise the cost will double in the later stage.

Of course, if the floor of the user's home has been paved, it is recommended to make a floor fan, which is better than a radiator. Because radiators first occupy too much area, and the second thermal efficiency is relatively low, if radiators must be used, the number of radiators should be multiplied by 2 according to the ratio of wall-mounted furnaces and radiators, and copper-aluminum composite radiators should be used Or a dedicated low-temperature radiator.

experience 2

Closed secondary system for home improvement two-way supply

For home installation of small dual-generation systems, it is recommended to install the secondary system with a location, because the secondary system unit is not affected by the full opening rate of the end, the operation is more stable, and it is also convenient for troubleshooting. However, when the area is less than 120 square meters and the installation location is very limited, a closed primary system is mostly used. (The primary system is simple and easy to install. At the same time, the primary system responds faster than the secondary system when cooling in summer. In addition, one less pump can reduce several failure points and reduce the cost. The disadvantage is that when the full opening rate is low, The unit is prone to failure).

experience 3

Add pure water to the system

Many of us may not have paid much attention to this water quality problem when installing the combined heating and air conditioning system. Because the water quality varies from place to place, the content of calcium and magnesium ions in some water is relatively low, so it may not be a big problem to add it to the system. However, in some areas, the calcium and magnesium ions in the water are particularly high. If they are added to the system, they will be used for a year or two at most, which may cause blockage of pipes, Y-type filters, water pumps, and units, which will seriously affect the use.

In addition, in areas where the temperature is relatively low in winter, it is recommended to use antifreeze. Generally, there are instructions for antifreeze, or add alcohol to antifreeze in pure water. If alcohol is used, it is recommended to add 9° industrial alcohol. The amount of alcohol depends on the actual situation and the amount of circulating water in the system. to adjust. For example, the amount of circulating water in the system is 100, add one kilogram of alcohol, the alcohol content of the water is basically 1%, then the freezing temperature of the water is -1°C. If five kilograms of alcohol are added, the water content in the system is 5%, so it can resist the environment of -5°C (no freezing).

In many areas, the temperature is low in winter. When the user does not use floor heating or the power is cut off for a long time at night, it is easy to cause the pipeline or unit to freeze and crack. Therefore, it is necessary to add a certain amount of antifreeze or alcohol.

experience 4

The fan coil must be equipped with a two-way ball valve

Without a two-way ball valve, some rooms will feel cold air coming out of the air outlet when not in use, and the power consumption of the system will be slightly higher. The installation position is at the water outlet of the fan coil unit, and in the whole system, if there are 5-6 fan coils, at least one fan coil should be equipped with a three-way ball valve. After the two-way ball valve is installed in the cold area of the north, if the room is not used, there is a possibility of freezing and breaking the copper pipe of the air coil. The solution: first, do not install the two-way ball valve in cold areas; second, use antifreeze.

experience 5

The recommended pressure for the home-installed small dual-supply system is 4 kg

It is generally better to use a closed system for the home improvement dual supply system. The recommended pressure is 0.4 MPa or 4 kg, the maximum should not be greater than 6 kg, and the minimum should not be less than 1.5 kg. If the system pressure is too low, the resistance of the pipeline will increase, and the water pump will be more likely to enter air. If the system pressure is too high, the valves and pipes will be prone to rupture or water leakage.

Experience 6

All piping must be insulated

Whether we are doing home improvement dual supply systems or hot water projects, the indoor pipes, especially the pipes in the ceiling layer, must be insulated, especially the dual supply systems, and the condensate drainage pipes should also use insulation cotton. And tie it with tape to prevent leakage of condensate.

experience 7

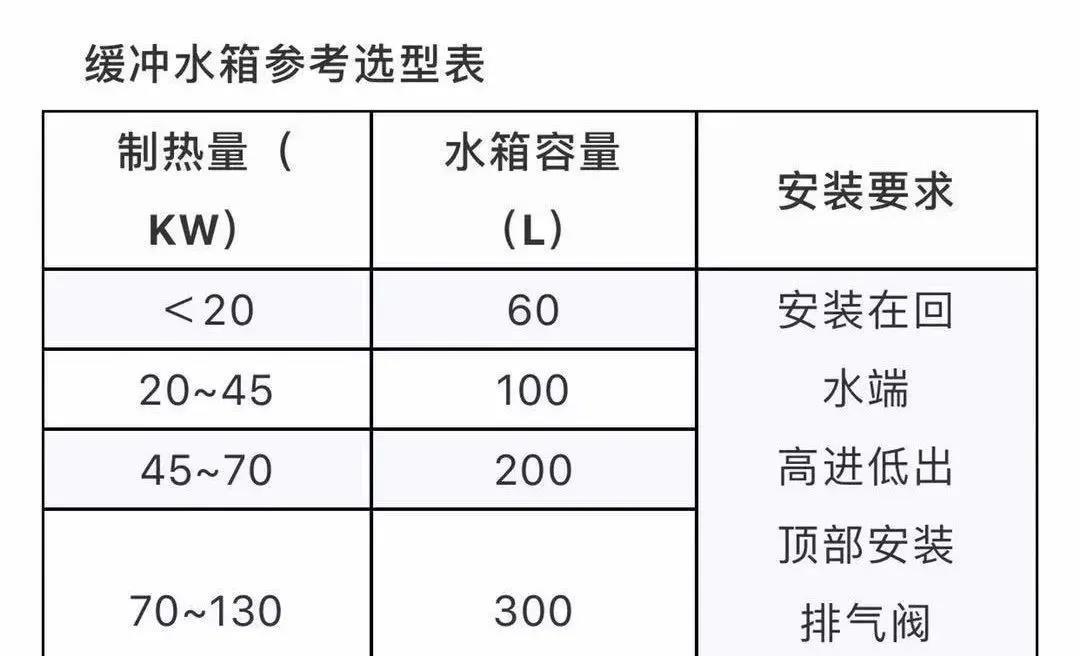

The installation of the buffer tank in the system is more energy efficient

In addition to the functions of heat storage and balance system stability, the buffer water tank also has the functions of exhaust and sewage discharge.

Note: ① The energy storage water tank is easily affected by the total water capacity of the water system, the number of units used at the same time at the end, and the configuration of the air conditioner host. Generally, the total water capacity of the system is 6~10L/KW heating capacity, and the larger value is selected for the lower number of units used at the same time. ②Calculate the total water capacity (6~10L/KW×unit heating capacity KW)-the actual water capacity of the current system=the capacity of the energy storage water tank.

experience 8

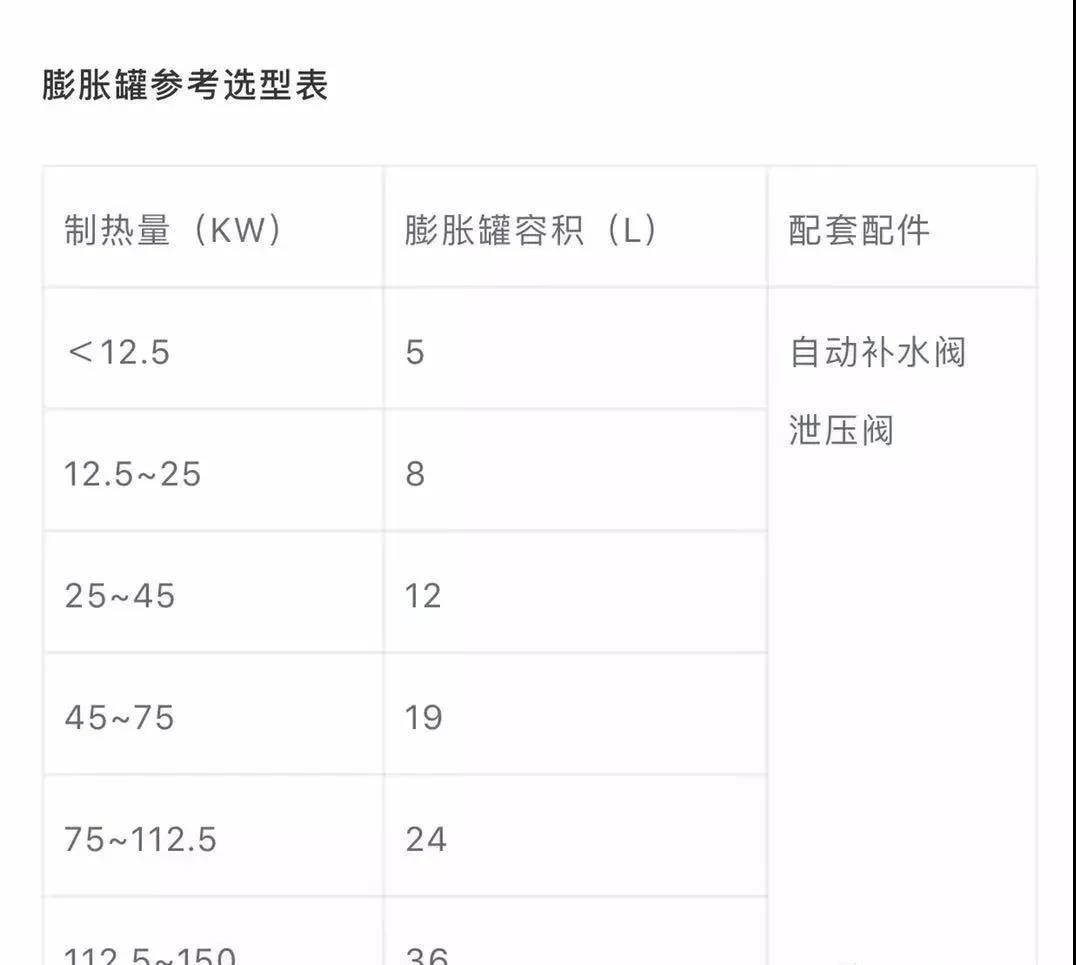

The buffer water tank has been installed in the system, and an expansion tank needs to be added

As long as it is an open or closed water circulation system with a water pump, regardless of whether there is a buffer tank or not, an expansion tank or a high-level expansion tank must be used. The expansion tank is not only the effect of the thermal expansion of the digested water, but also has an important function of "constant pressure", so the expansion tank is also called the constant pressure tank. If the expansion tank is not installed or the model is selected incorrectly, there will definitely be frequent accumulation of gas and unclean discharge. Many failures of the water system occur frequently, which may be caused by unscientific local installation.

Note: ① It is better to choose 304 stainless steel flange for the expansion tank, and the galvanized carbon steel is easier to rust. ②The pre-filling pressure of the expansion tank is equal to the setting pressure of the filling valve. ③ It is recommended to check the inflation pressure of the expansion tank every 1 to 2 years, and inflate when the pressure is low.

experience 9

An automatic exhaust valve should be installed at the highest point of the system

In the case that the location of the water tank of the home-installed dual-supply system is not easy to determine, we have to determine it according to the site conditions. It is of course better if it can be installed at the highest point. However, in some cases, it can only be installed on the ground or lower, so the exhaust problem must be considered in the system. If the water tank is installed higher than the system pipeline, an automatic exhaust valve can be installed on the top of the water tank, because the fan coil and Floor heating has a manual exhaust valve.

If the position of the water tank is lower than the system pipeline, in addition to the buffer water tank must be equipped with an automatic exhaust valve, the highest part of the system's water inlet and return pipes must also be equipped with an automatic exhaust valve, otherwise if the pipeline enters air, the light will increase The impact of large water resistance will lead to air blockage in waterways and impeded circulation in severe cases.

Some people will say, isn’t the system under pressure, how can air enter? Because in winter, when heating with floor heating, some air in the water will be released.

experience 10

The system main pipe must be straight

The main pipeline of the whole system must be straight, and it is best to go uphill slightly along the direction of water flow. The water inlet pipe is slightly lifted up, and the return pipe is slightly lowered, which can facilitate the discharge of air in the pipeline, and the main pipeline must not be U-shaped. , It will form an air block, even with a soft connection.

——This article comes from the comfortable home furnishing industry