Product Center

Heat pump high temperature dryer

Through the advanced heat pump energy-saving technology provided by the United States ATSE, combined with the in-depth research and development of Tianjin University Institute of Thermal Energy, now has RMRB independent brand. RMRB company has eight series of more than 40 models, in addition to domestic and commercial heat pump hot water units, but also creative development of water-loop household heat pump, cooling, heating and heat triple supply, seawater removable breeding heat pump, with high scientific and technological content and independent intellectual property rights.

Tel:

Keywords: RMRB heat pump, commercial heating and cooling heat pump, drying heat pump, inverter central air conditioning

- Describe

-

RIM heat pump drying technology introduction

Heat pump dryer is a kind of equipment used for drying items, also known as heat pump dryer. The material drying process is a huge energy-consuming process. According to statistics, in most developed countries, the energy consumed for drying accounts for 7%-15% of the total national energy consumption, while the thermal efficiency is only 25%-50%. , and most drying processes, especially for heat-sensitive materials (such as food and biological materials), will affect their color, nutrition, flavor and texture. Heat pump drying technology has the advantages of less energy consumption, less environmental pollution, high drying quality, and wide application range. Its excellent energy-saving effect has been proved by various experimental research institutes at home and abroad.

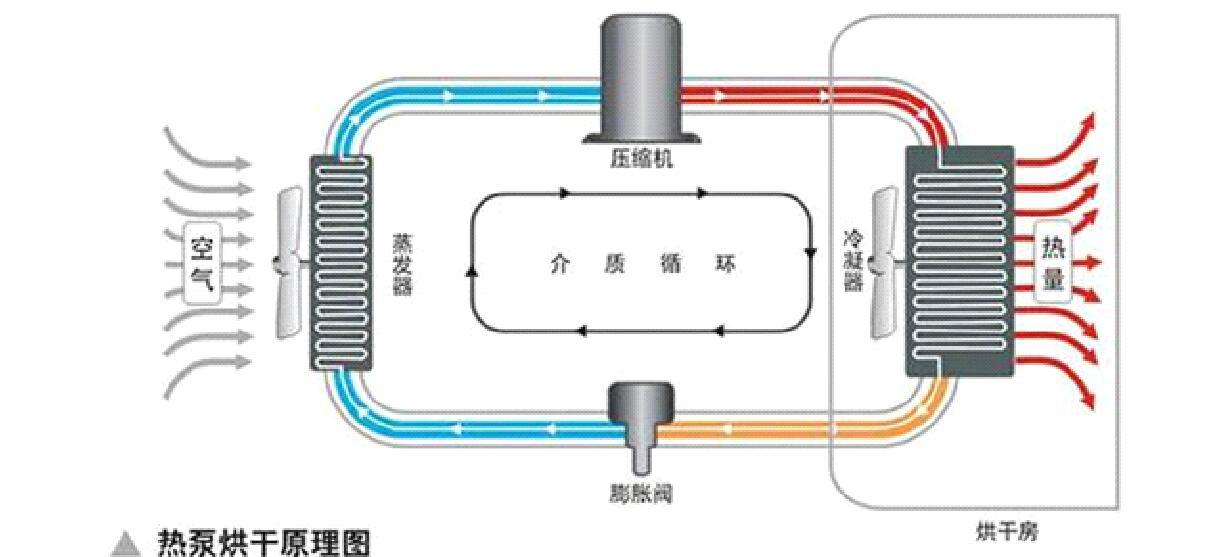

Drying heat pump principle

The heat pump dryer uses the reverse Carnot principle to absorb the heat of the air and transfer it to the room, so as to increase the temperature of the drying room, and cooperate with the corresponding equipment to realize the drying of the material. The heat pump dryer consists of a compressor, a heat exchanger (inner unit), a throttle, a heat absorber (outer unit), a compressor and other devices to form a circulation system. The refrigerant circulates in the system under the action of the compressor. It completes the gaseous boosting and heating process in the compressor (temperature up to 100°C), it enters the internal machine and releases high-temperature heat to heat and dry the air in the room, and at the same time it is cooled and transformed into a liquid state, when it runs outside After cooling down, the liquid state quickly absorbs heat and evaporates into a gaseous state again, and at the same time the temperature drops to minus 20°C--30°C. At this time, the air around the heat absorber will continuously transfer heat to the refrigerant. The continuous circulation of the refrigerant can transfer the heat in the air to the drying room to heat the air temperature in the room.

RIM heat pump dryer has the following characteristics

Adopt world famous brand compressor, four-way valve and throttle valve, the performance of the unit is more stable and superior

Microcomputer LCD controller, no need for special guards

Quick and easy installation

Environmental friendly, no pollution

High energy efficiency, save money

Efficient heat recovery, heat recovery up to 60%

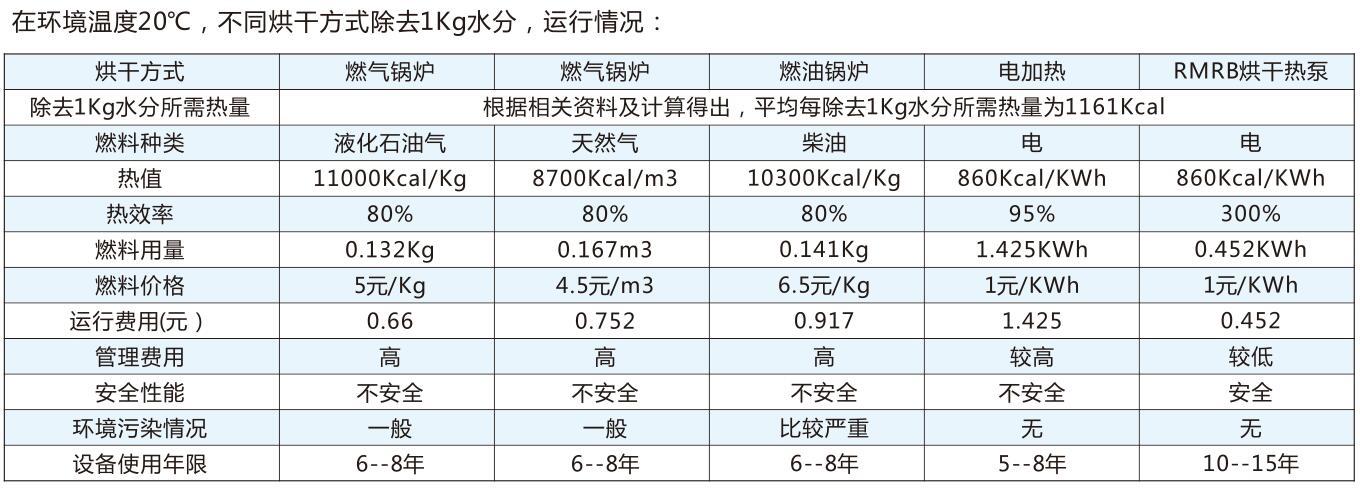

operation distraction comparison

Related Products

Product Message